Leather Testing Week

- Fenna Engelke

- Sep 10, 2019

- 3 min read

Updated: Sep 16, 2019

Monday

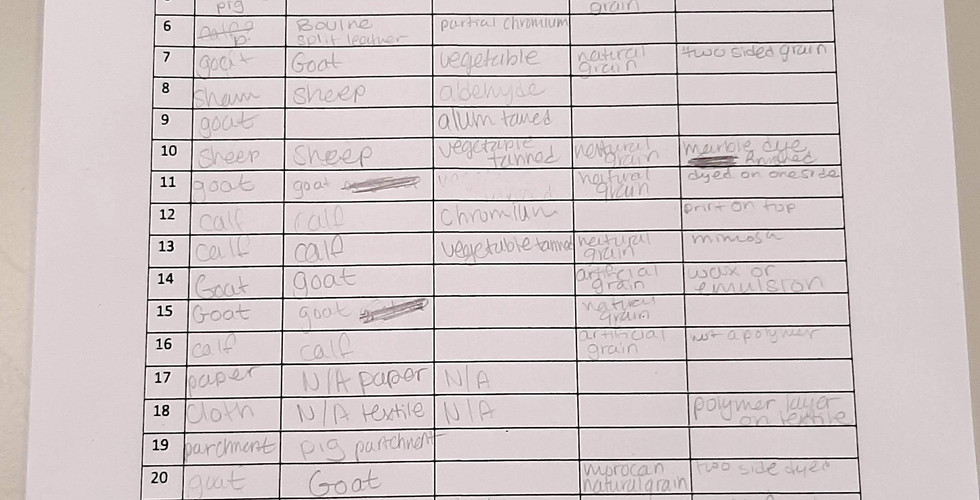

Monday was spent primarily on reviewing last years' material on leather as well as introducing more information on the history of tanning methods. The second half of the day was spent on identifying the species of animal used for various leather samples. We also tried to identify if the samples had natural or artificial grains.

Tuesday

Tuesday morning started with a presentation on the chemistry involved with leather and was spent comparing hydrolysable and condensed tanning agents. The afternoon was spent with a sample square of leather on which we created various fills and tear mends and compared several adhesives. The adhesives compared were: parchment glue, EvaconR:MC (5% solution) 1:1, BEVA adhesive tape, and Klucel G.

For each adhesive I attempted to do a leather fill, a Japanese paper tear mend, and a tyvek tear mend.

All acted rather successfully although the Klucel G was not strong enough to hold the tyvek to the leather sample. The Klucel G used for the leather fill also bled through to the front of the sample and stained the leather. I'm unsure if this was due to the Klucel G or the Leather which was used for the fill.

The later part of the day was spent on a leather shrinkage test where 4 stripes of different leathers were partially submerged in gradually heated water until the leather shrunk due to the temperature.

Wednesday

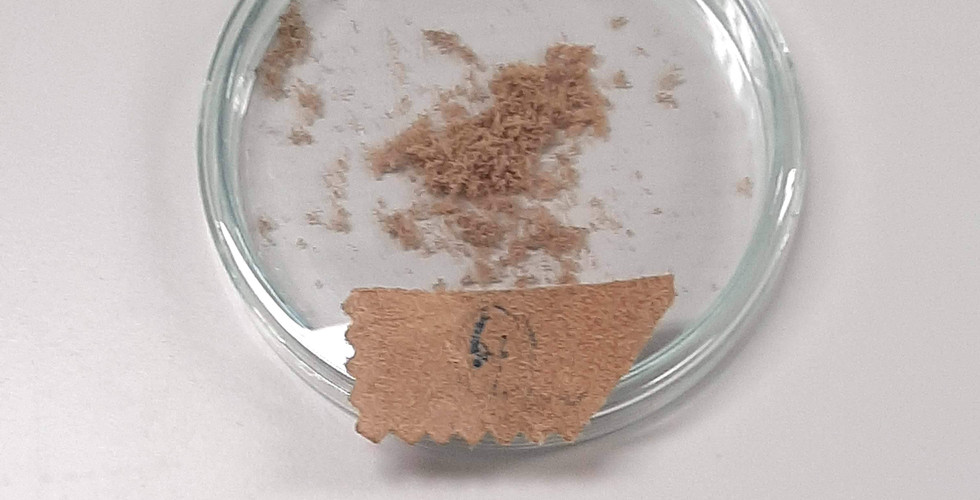

Wednesday morning was spent in lab coats. Each of us were given a leather sample which we then had to test for tanning agents. We tested for vegetable tannins, gallic tannins, and condensed tannins. The flesh side of the leather was scrapped to create bits of sample fibers which were then subjected to tests.

Vegetable tannins: add a drop of DI water to the leather scraps, remove excess water. Add two drops of 2% iron(iii)chloride. If the sample turns black, vegetal tannins had been used on the leather.

Gallic acid and Gallotannins: Add two drops of rhodanine reagent (0.667%), wait five minutes, and then add two drops of potassium hydroxide reagent(0.5N).

Condensed Tannins: Work within a fume hood for this test. Add two drops of vanillin reagent (1% vanillin in ethanol), then add two drops of hydrochloric acid (37%).

Later, a fourth test was given for the presence of Chromium. A strip of the samples were burned and the ashes were checked for a change in color. If the ashes were green, it indicated the presence of chromium.

My sample had been sold and advertised as a sumac tanned leather. Results of testing showed that my sample, #4, tested positive of vegetal tannins, positive for gallic tannins, and negative for condensed tannins. This means that it is possible the the leather was sumac tanned leather, as advertised.

#7 and #9 both tested negative for the solution tests but later tested positive for chromium when we did the burn test.

Below is a table of the results, with ~ meaning that there was a reaction but not a strong one. The sample #8 was not tested and is indicated with a -.

Thursday

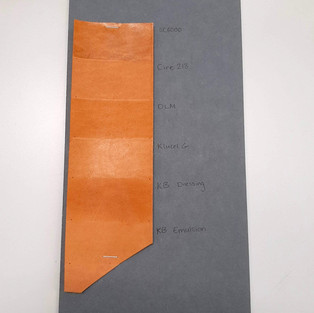

Friday we had the great opportunity to have a guest lecturer, Dr. Laurianne Robinet, who went over more of the science behind leather that morning. The afternoon was spent on looking at leather dressings, emulsions, and waxes. We took a sample piece of leather and coated sections of it with various coatings to see the differences between them.

The coating materials used are as followed:

SC6000

Cire 213

DLM

Klucel G

KM leather dressing

KM leather emulsion

After everyone had created a sample leather with coatings, there was a group discussion over one of the readings for the week, Kristina Blaschke's 2012 publication "Lubricants on Vegetable Tanned Leather: Effects and Chemical Changes", Restaurator Vol. 33, pg. 76-99.

Comments